We’re going on a field trip, back to middle school chemistry class. Do you remember the experiment with salt water, a battery, and two pencils? Guess what? The reaction you witnessed then is a key to tackling climate change. Yes, at 14 years old, we already knew. Today, we have the means to replace fossil fuels with green hydrogen. Let’s walk through this.

The Science Behind Green Hydrogen

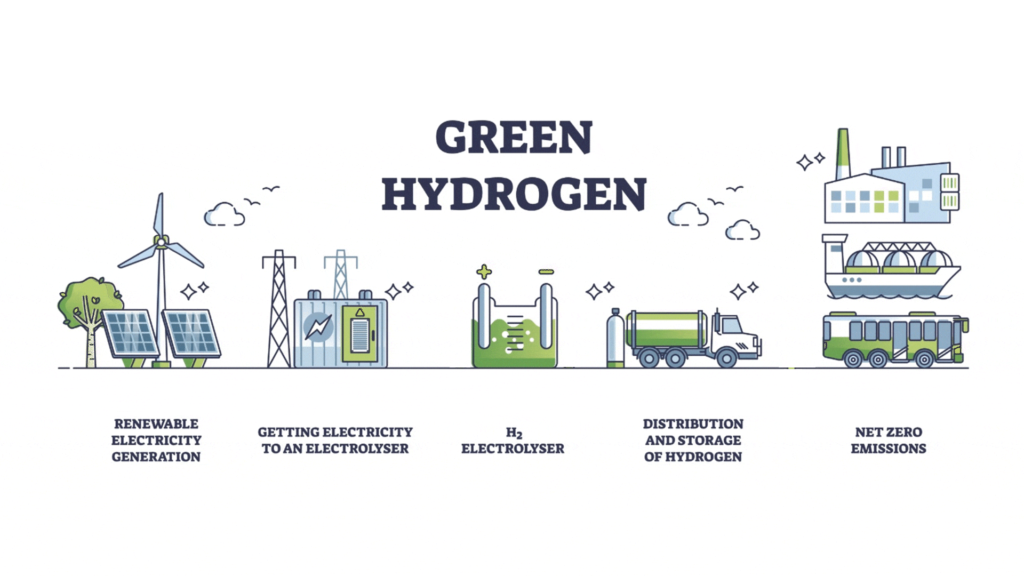

The experiment I’m alluding to is called water electrolysis, a method to create hydrogen on Earth. Hydrogen is found in the greatest quantities in water (H2O). When renewable electricity is used to split water into hydrogen (H) and oxygen (O), that’s green hydrogen. The device facilitating this reaction is called an electrolyzer. While there are other types of hydrogen, they rely on fossil fuels and exacerbate climate change. We are focusing on green hydrogen, which is 100% clean. The quickest path to scaling green hydrogen is by mass-producing electrolyzers.

Why Do We Need Green Hydrogen?

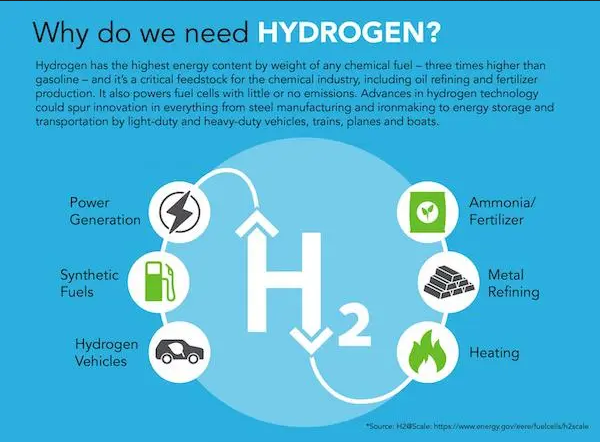

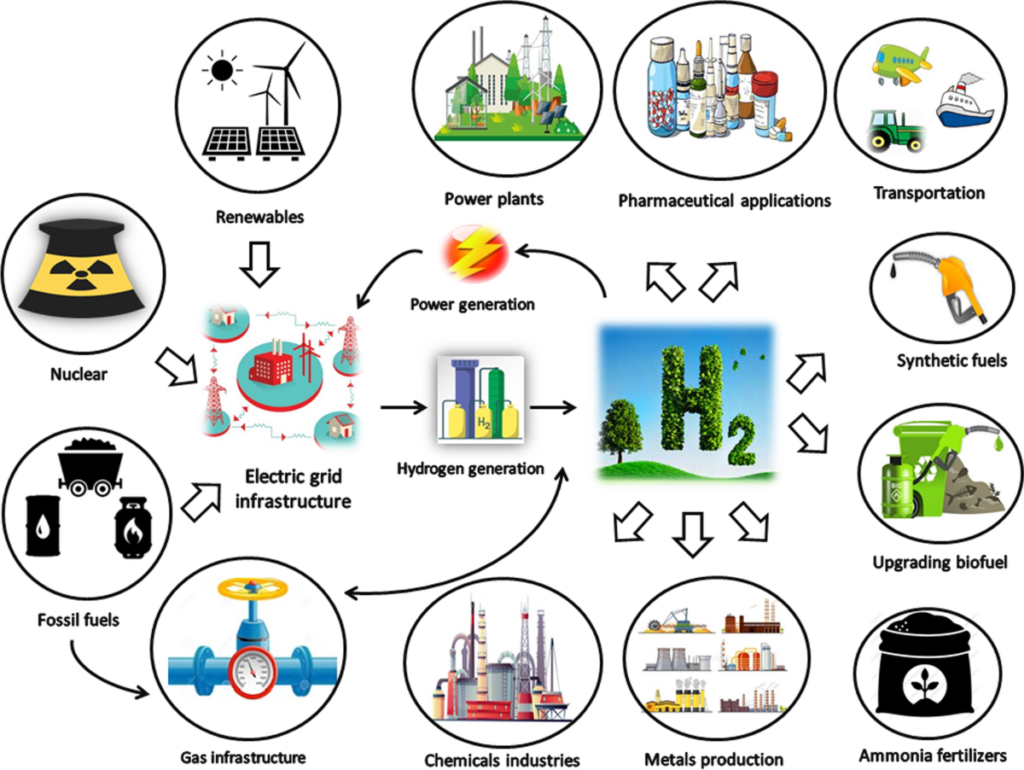

When we examine our global energy consumption, only 20% comes in the form of electricity or electrons. This means the remaining 80% of our world’s energy use is in the form of molecules. While the world is rapidly advancing in greening our electricity, we need to address our molecules as well. Think about the industry, transport, heating, and cooling sectors. They’re all powered by molecules—primarily fossil fuels like coal, oil, and gas. We won’t be able to electrify all sectors, and here’s why.

Let’s start with an example from the industrial sector. In steel production, molecules create the reaction, not electrons. To make steel the old way, we first mine iron ore and then burn coal to remove the oxygen from the iron mix. This process accounts for 7 to 9% of our world’s CO2 emissions. It’s the coal that provides the molecule needed to remove the oxygen. Electrons can’t do that, but they can power the device that creates green hydrogen. This clean molecule will create the reaction, attract the oxygen, and emit only water in the process. By changing the process, we can eliminate up to 95% of our CO2 emissions. Major European steel manufacturers are already building green hydrogen-based steel production processes.

Another example is aviation. An 80-passenger aircraft flying on batteries is kind of impossible; it would require more batteries just to fly the battery. However, hydrogen planes are taking off emission-free. A 20-seater aircraft is scheduled for commercial flights in two years, and by 2026, we’ll welcome the 80-seater.

The Versatility of Green Hydrogen

These are just two examples of how we can end our reliance on fossil fuels. The world is turning to green hydrogen because it effectively couples hard-to-decarbonise sectors with green electricity. An electrolyser connected to solar and wind power generation is transforming green electrons into green molecules. Green hydrogen is transforming our renewable electricity into an energy carrier that is extremely versatile.

Today, this clean molecule is already being used in a wide range of applications. It can be combusted directly as a fuel and emits zero carbon emissions. It’s also being turned into hydrogen-derived fuels like green ammonia and green methanol, which can fuel global shipping. Green hydrogen is being stored across seasons without losing energy, like in the Alps. It can then be used in a fuel cell to create electricity, emitting only water. Hydrogen is one of the most energy-dense molecules and, by mass, contains three times as much energy as diesel.

Challenges and Innovations in Green Hydrogen Production

You might be wondering, why aren’t we using this everywhere already? Previously, the cost of green electricity was the bottleneck, but that’s no longer the case. The current challenge lies in the speed, scale, and cost of making these green hydrogen generators. Fortunately, people are working diligently to make green hydrogen a reality. To make green hydrogen the fuel source of the future, it needs to be cheaper than fossil fuels. This means electrolyzers must be extremely affordable.

We started Enapter in 2017 with this goal in mind and urgency in our hearts. We chose a different approach from others in the industry. We turned to economic history for strategies that scaled fast and reduced prices significantly. The answer was clear: if you want to take a solution global quickly, you need to make it a standardised, mass-produced commodity—a product that’s easy to make and use. Some believe we need larger machines, but we believe the electrolyser should be a standardised, mass-produced commodity that can make green hydrogen anywhere for anyone.

The Path Forward: Mass Production and Innovation

To better understand our approach, let me draw an analogy. Up until the 80s, mainframe computers were considered the future of computing. They were huge and complex, designed for businesses only. Then came the PC, and at first, people laughed and wondered why we would ever need such a tiny computer. But ultimately, it disrupted the industry. Today, data centres use blade servers, which is PC technology. Why? Because the PC became a compact, standardised, and mass-producible product that was cheap to make, easy to build, and could be used in any context. It’s time to do this with green hydrogen.

Enapter is designing all of its electrolysers as products, not projects. At the heart of our electrolyser is an electrolysis core generating green hydrogen, and it is the foundation for all of our products. We’re taking these core stacks and other components of our electrolysers into mass production. Instead of building larger electrolysers, we’re building compact ones that can be combined to achieve any hydrogen quantity needed. We believe this is the quickest way to scale green hydrogen and drive down its price.

The next step is going into mass production. Our campus will be fully powered by renewables, of course, and that’s where we’ll tackle speed, scale, and cost. By focusing on one single core size, we can leverage massive economies of scale and drive down the price of green hydrogen. Because that’s what it’s all about making green hydrogen cheaper than fossil fuels.

We have the means to make green hydrogen the fuel source of the future. It’s time to listen to our 14-year-old selves and the 14-year-olds of today. Our generation has a unique opportunity. It’s time for the next industrial revolution. We can build our world’s energy supplies sustainably, made of a lot of green electricity and a wave of green hydrogen molecules. This is how we end the fossil fuel era. Thank you.